A torque converter is one of the most important components of transmission in modern motor vehicles equipped with an automatic transmission or a variator. This transmission assembly may be referred to as the converter, hydrodynamic torque converter or torque converter. But our specialists and just car enthusiasts call it simply and gently - donut. And this is quite justified - many converters really look like this confectionery. In this publication, TransTrade specialists collected all the necessary introductory information on torque converters, including operating principle, application and utmost importance of timely replacement of a worn-out torque converter with a new or professionally repaired one.

How Does a Torque Converter work?

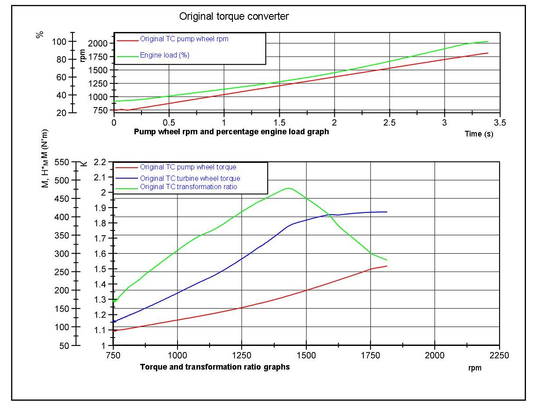

A torque converter in automatic transmissions performs several important functions at once, therefore it is considered one of the most important assemblies of automatic transmission. In addition to the basic function of clutch, a torque converter transmits torque from the internal combustion engine (ICE) to transmission elements by automatically changing it in proportion to speed of car wheels and existing load.

A "donut" comprises the following parts:

Centrifugal pump (or pump wheel)

- Lock-up clutch

- Centripetal turbine (turbine wheel) directly splined with automatic transmission shaft

- Reactor located between the pump and the turbine

- Overrunning clutch

A modern torque converter is designed with two vane assemblies (a pump and a turbine) being as close as possible in its housing, and their wheels are shaped to maximize noninterruptible and uniform circulation of working fluid (transmission oil). This design allowed a torque converter to be quite compact and very ergonomic and cost effective, since this arrangement minimizes energy losses when oil flows from one wheel to another.

The pump wheel is mechanically coupled with ICE crankshaft and the turbine wheel, as already mentioned, with automatic transmission shaft. This ensures that there is no rigid contact between the driving and driven parts, energy is transmitted from ICE to transmission and then to wheels through the directed flow of working fluid. In general, the operating principle of torque converters has much in common with operation of a fluid coupling, which is the predecessor of a torque converter.

Where to fix a torque converter?

If a serious wear or breakage of a torque converter is found in your car, call TransTrade and your problem will be solved as soon as possible with above 90% probability! You will simply get your faulty torque converter replaced with a professionally repaired one at a very affordable price! And if suddenly your particular model is not available, your torque converter will be overhauled within at most a few hours!