During repair of torque converters, we were often asked whether it is possible to change speed performance of a car by replacing a standard torque converter with that having modified performance, while not degrading other operating characteristics of the car such as fuel consumption, driving comfort, etc. There are many theories regarding tuning of torque converter. Some believe that turning makes the car to accelerate faster and it seems that the performance has really changed. Others believe that it causes more harm than good: car acceleration changes slightly, engine speed increases, fuel consumption increases, etc. Theories can be listed indefinitely, from those that may be logically justified to those that directly contradict the laws of physics.

Here, we try to answer some of the questions that arise. What performance will improve and deteriorate? The price of a tuned converter in the US market is 3-15 times higher than that of a standard one, so is it worth for a car owner to pay such expenses?

Theory

During operation, torque converter experiences constant changes in speed of pump and turbine wheels; this ratio (ratio of turbine wheel speed nt to pump wheel speed np) is called a gear ratio of the torque converter.

![]() (1)

(1)

From the laws of hydraulic transmission it follows that a torque applied to pump and turbine wheels is based on the following dependence:

(2)

(2)

(3)

where:

• сp,сt - torque factors of pump and turbine wheels, respectively

• np,nt - speeds of pump and turbine wheels, respectively

• Da - active diameter of the torque converter corresponding to maximum diameter of the circulation circle.

The torque converter performance means a curve that reflects the dependence of variation in torque factor "c" on gear ratio of torque converter i.

The torque transformation ratio K is based on the ratio of torque of the turbine wheel to torque of the pump wheel of the torque converter:

(4)

(4)

Tests

To understand in practice the difference between a standard torque converter and a torque converter with increased Stall RPM, let's conduct the following experiments. Measurements and tests will be performed on torque converters of General Motors 6L80 six-speed transmission. It was introduced at the end of 2005 and is still quite common on the market, it was installed on such cars as Cadillac XLR, STS-V, Escalade, Chevrolet Corvette, Silverado1500, Silverado 2500HD, Tahoe, GMC Yukon Denali and other GM models. This type of torque converter was used on cars with engine capacity of 4.8, 5.3, 6.0 and 6.2 L. For example, we give specifications of the 5.3 L engine:

1. * Power: 315-320 hp (235-239 kW) at 5200 rpm

2. * Torque: 335-340 ft-lbs (454-461 Nm) at 4000 rpm

In our tests, we will compare two JMBX torque converters, standard one and purchased one from a tuning company.

This company says that thanks to tuning, the torque converter has Stall RPM 500 rpm more than the standard one.

All measurements will be conducted on a specialized bench with electric motor having maximum torque of 268 Nm at 1800 rpm.

The test will be performed as follows.

We secure the output shaft, thereby stopping the turbine wheel, and start turning the pump wheel, thus simulating Stall-test on a car, or stall operating mode of a torque converter.

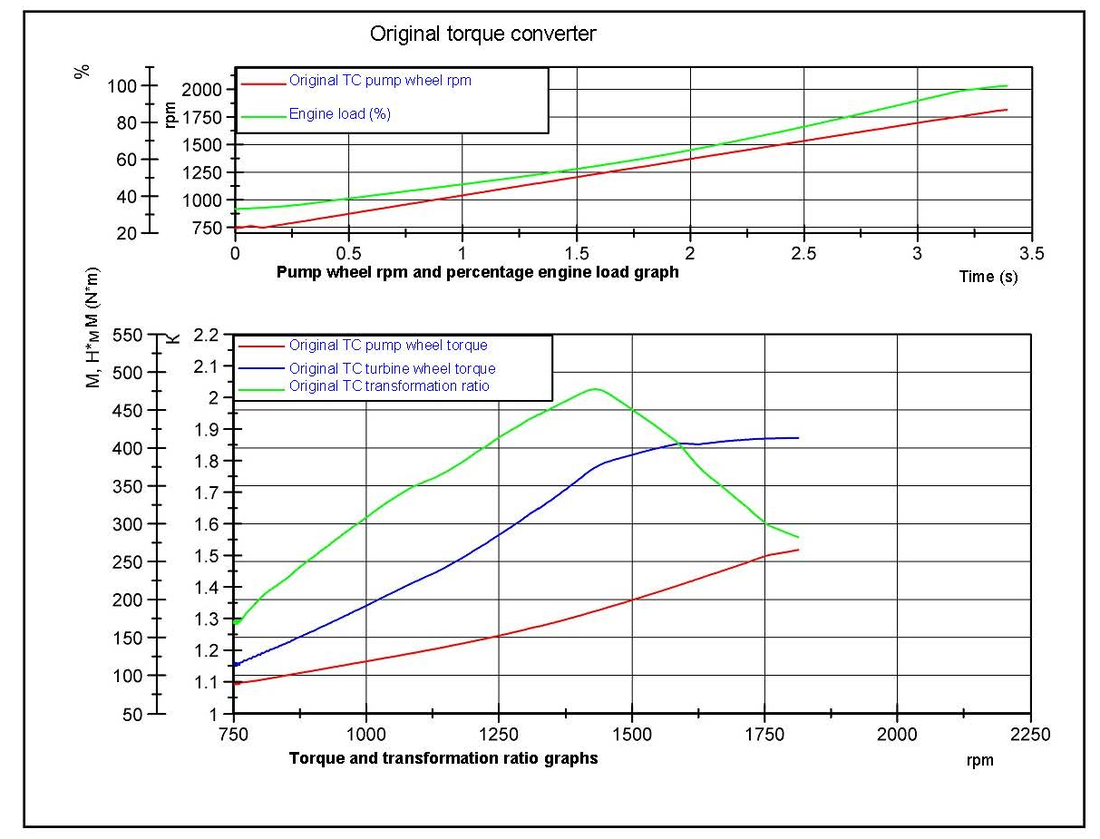

For a start, we will present specifications of a standard torque converter and, with preliminary calculations made that exclude effects of gear ratio of planetary gear sets, we will obtain the following dependencies: (Figure 1).

Next, we will test the torque converter with increased Stall RPM and also present the obtained values on graphs: (Figure 2).

Based on the fact that we perform a test with the turbine wheel stopped, pump wheel rpm will be slippage rpm of the pump wheel relative to the turbine wheel. It immediately noticeable that for a standard torque converter, maximum torque is obtained on the pump wheel at 1760 rpm, and for a torque converter with increased Stall RPM - at 2200 rpm.

For a comparative characteristic of these converters, let's select several points.

Do not forger the accelerator

The first point to pay attention to is idle rpm. For original torque converter we obtain a torque of 110 Nm at 750 rpm. With increased Stall RPM at the same 750 rpm, the torque reaches only 75 Nm which is 32% less than that of the original torque converter. In this case, it is very likely that when brake pedal is released in Drive or Reverse position, 2.5-ton car will not get off the ground. And to obtain the same torque on the turbine wheel of the torque converter as on the original one, the engine speed will have to be increased up to 900 rpm.

The torque converter under test (Stall 500 rpm higher than the standard one) is only the first step in the range of converters with increased Stall RPM. Transformers with Stall RPM of 2800, 3000, 3200, 3600 rpm are also widely available. Accordingly, when using the latter, we will move even further into the region of higher rpm in to obtain the same torque as on the standard torque converter at 750 rpm. Is it convenient, while standing in a traffic jam, each time the car starts, not only release the brake pedal, but also increase engine rpm? It's up to driver to decide whether he is ready to accept it.

Further, having compared the graphs of ratios, we will see that their values are the same and equal to 2.04, that is, the torque on the turbine wheel may increase as many times as compared to the pump wheel. In other words, on this torque converter, due to high slippage rpm, we will not increase the torque on the automatic transmission output shaft anyway, and we can only increase the torque on wheels by shifting the engine operating condition to high-torque rpm region.

When analyzing characteristics of engine rpm and torque ratio, it is important to note that the peak of ratio shifts to higher rpm region. And the higher the value of Stall RPM is, the more we will shift to high rpm region. In terms of percentage of engine rpm for the compared torque converters, excess will be 20% more than the standard one. Also, to obtain the same engine load, i.e. torque on the pump wheel, we need to accelerate the engine with Stall RPM using a torque converter up to 2200 rpm instead of 1760 rpm, as on a standard one. By superimposing speed performance of the engine on this dependence, we obtain even greater non-linearity in engine rpm and engine load.

Having differentiated torque ratio functions with respect to time, we will notice the following dependencies: (Figure 3).

It can be seen from the graph that torque rates are approximately the same. This indicates that starting a car with High Stall converter shall not be followed by shocks and will be approximately the same as with the original one, only at higher rpm. This dependence cannot be applied with 100% certainty to other torque converters with higher Stall RPM since their specifications may differ.

For efficient use of engine power and torque converter, their specifications shall be matched. Now, to evaluate the acceleration of a car with different torque converters, we need to turn to the theory for a while again.

Earlier we said that one of the main characteristics of a torque converter is its dependence of variation in torque factor c on torque converter gear ratio i. In case of a transparent torque converter (where a variation in torque and speed of the turbine wheel causes a corresponding variation in torque and speed of the pump wheel) each gear ratio of the torque converter corresponds to a certain value of сp. Then, according to equation (2), loading parabolas are constructed corresponding to certain values of gear ratios i until they intersect with the external curve of the engine.

torque Me. The graph (Figures 4) shows variations in the engine torque and loading parabola corresponding to different torque converter gear ratios, including its boundary values at i_0=0 and i_b=0.975.

Intersection points of Мe and Мp curves on the input characteristic are based on a crankshaft speed. If the curves intersect in stall conditions (i=0) at low rpm, this will have a negative effect on car's acceleration.

For torque converters under test, we will experimentally obtain torque factors at different torque converter gear ratios (by changing the load on the turbine wheel at constant rpm of the pump wheel) (Figure 5).

Using data of graphs presented above and formula (2), let's plot the graphs of torques of the pump wheel at various gear ratios (Figure 6):

They show that for High Stall RPM torque converter, the loading curves are shifted to the higher rpm region, thereby approaching engine rpm with maximum torque. Based on specification of gasoline naturally aspirated engines we can say that the difference is approximately 450-500 rpm, which corresponds to its declared specifications.

In other words, when a car starts accelerating, the engine accelerates with a higher torque. By superimposing the external speed performance curve of the engine on curve Мp (Figure 6), we can obtain the torque realized during car acceleration with the given specifications of the torque converter.

The performance curve of the torque converter may be increasingly shifted to higher rpm region, thereby obtaining higher torque when a car starts accelerating. The intersection of torque curves of the torque converter pump wheel with the engine performance curve beyond the point with maximum engine torque is unacceptable since no maximum engine torque will be realized during acceleration.

Accordingly, all car acceleration parameters may be obtained only by knowing full external speed performance of the engine.

Also, the issue on operation of automatic transmission control unit remains open when selecting any gear on a torque converter with high Stall RPM since parameters of engine rpm, output shaft rpm, throttle position, accelerator pedal

position and many other parameters are taken into account during gear calculation. When using a standard control unit, it will likely to shift gears not in optimal engine operating conditions, and this, in turn, may adversely affect car acceleration. Better car acceleration may be achieved only by using the manual gearshift mode on a torque converter with high Stall RPM.